Description

Introduction

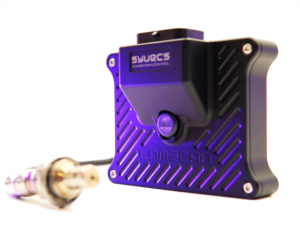

The Syvecs OEX (Oe Ecu eXpander) is a powerful expander module enabling advanced after market features on existing OEM engine management systems via CAN/CANFD communication. By utilising the well proven Syvecs X20 hardware which was born in 2020, a version of the software has been created to provide our Syvecs market leading features into the Oe Ecu eXpander package. This provides the best solution for clients who need to expand the capabilities of an original ecu control module or to integrate with another engine control unit (Master).

Features

- 12 x Sequential injectors with closed loop feedback from Onboard lambdas or OEM readings

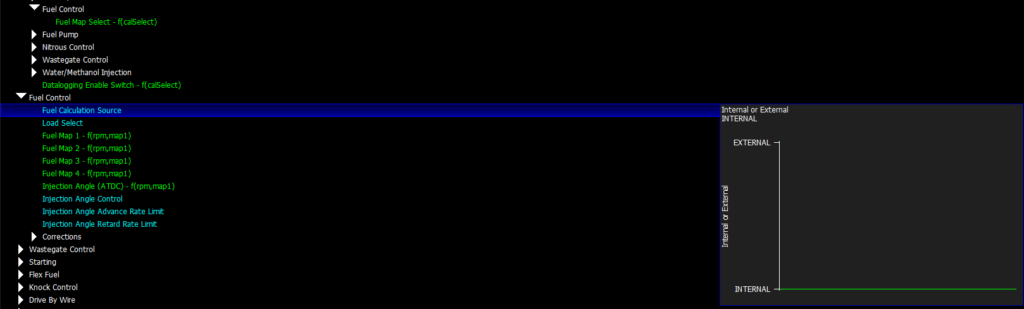

- Internal or External Fuel Calculations from multiple internal sources or external CAN targets from and OEM ECU (Master ECU)

- Live calibrating from SCAL software via USB C

- 2 x NTK Lambda Circuits for close loop fueling with option to pickup lambda targets from OEM ECU (Master ECU)

- Dual Wastegate Control with option of internal targets or external targets from OEM ECU (Master ECU)

- Dual Knock Control Circuits to externally monitor, warn and feedback to the OEM ECU (Master ECU)

- USB Datalogging to PC or External Memory Stick (up to 4000 times a second!)

- Flex Fuel Controls, change Injection parameters, boost targets and more

- Intregrates with MHD and Ecutek for Port Injection, Boost Control, External Output control and more

- Nitrous Control, wet or dry strategies with bottle pressure control

- External DBW Strategy for Older cars which want to add Drive by wire support

- LimpMode strategies with option to bring OEM ECU light on, adjust sensor voltage outputs to OEM ECU, lower boost targets, enable outputs and Limp CAN Messages

- Water injection Control with safety strategies for Level, Pressure and Flow from our WMI Module

- OBD2 Support - Pick up many OEM sensor readings including Lambda, Ignition Timing, Temperatures, MAF etc

- Lean lambda trip from our standalone Engine Control Module to add protection

- Traction Control calculation done internally on the OEX to reduce boost and send torque reduction the OEM ECU (Master ECU)

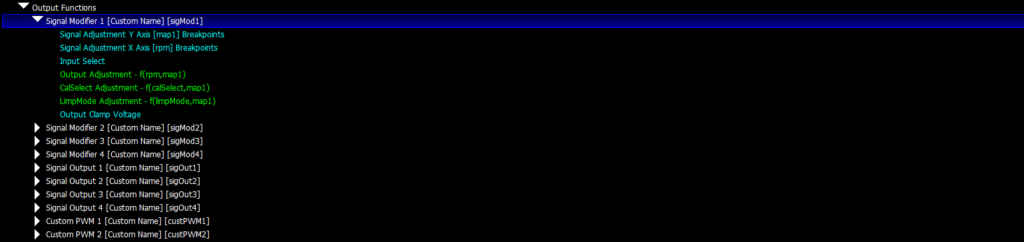

- Signal rescaling / clamping on 4 x DAC outputs to modify signals in the OEM ECU (Master ECU) like Manifold pressure sensors

- 20 x Analog inputs with frequency, thermistor and ADC support

- 20 x Output, 8 Half Bridge and 12 Low Side

- CAN / CANFD Support

- Optional FlexRay hardware available on request to allow all OEX functions on newer models of vehicles, software currently under development.

- Crank and Cam Setup strategies from our Standalone Engine Control modules

- CAN Bridging/Forwarding between 2 CAN Bus’s and ability to drop frames, then transmit own messages to keep OEM modules happy

- Water Resistant

and more

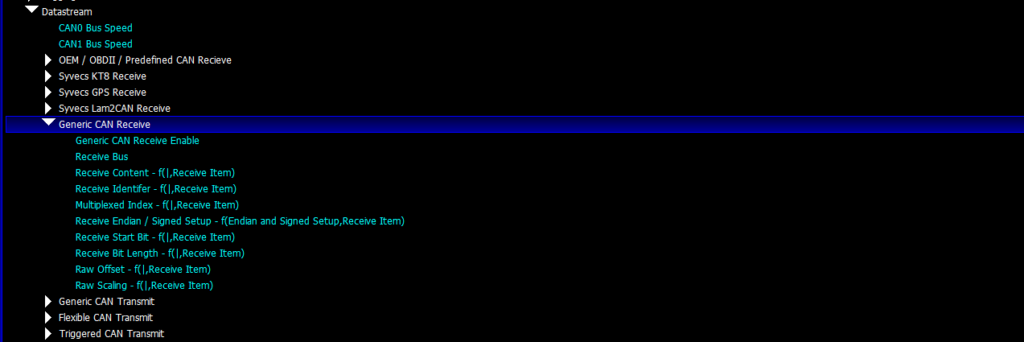

Extensive CAN integration

Syvecs is known industry-wide for our OEM/ECU CAN data capabilities, and the OEX is no exception. We have incorporated our most popular CAN database decodes into the OEX, allowing for direct communication with many powertrain CAN buses. This enables users to quickly retrieve information from their vehicle or aftermarket ECU, displayed in the OEX without the limitations of the OBDII protocol.

The OEX integrates with OEM Can bus systems in the following ways, all of which can be used to your advantage.

• Reading of OEM sensors such as Manifold Pressure, Air charge, Oil and Coolant temperatures.

• Reading of calculated loads such as Torque and Fuel trims, ignition advance and Load.

• Reading of measured values such as TPS, Speed and RPM, and OEM Lambda.

• Ability to manipulation the OEM CAN by forwarding through the OEX CAN0 and CAN1, Can then drop and modify data.

• The OEX can also produce can frames for sharing information such as LimpMode, enabling the OEM CEL light.

• OBD2 Communication to extract Data and also Clear DTCs or Enable modes such as DynoMode or ABS OFF

Triggered CAN messages are also available to send OEM diagnostic messages to clear DTCs.

If a vehicle/ECU is not listed, installers can use our Generic CAN receive/transmit function and configure their own CAN communication.

Engine Sync and additional Injection

The Syvecs OEX package allows up to 12 injectors to be controlled sequentially when the OEX is 720 synced to the engine. This requires the crank and cam signals to be connected to the OEX and set up correctly. Calibrators have the ability to define the crank and cam patterns in the software to accommodate nearly every type of trigger setup used in the automotive world. Once the OEX is synced to the engine, calibrators can decide how best to control the additional injectors, either via internal fuel calculations or external targets sent from the OEM ECU (master ECU), allowing control of injection time, injection angle, lambda targets, and bank/cylinder trims.

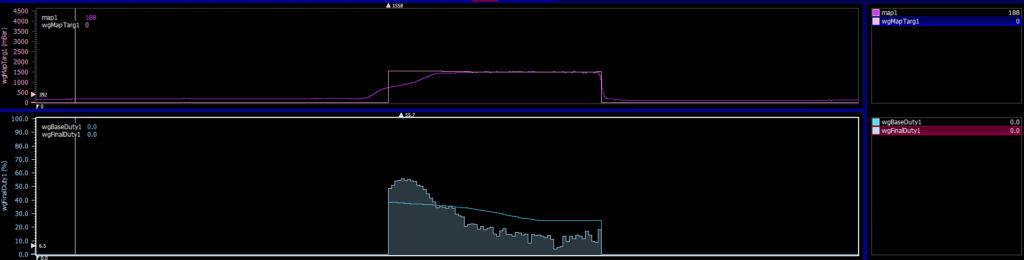

Boost Control

Dual bank closed-loop boost control is available, allowing calibrators to control internal or external wastegates with targeting from internal and external sources. The boost target can be adjusted via OEM buttons in the factory car or from external switches. Safety strategies are also in place, so in the event of over-boost, limp modes can be set to warn users via dash lights or by adjusting signals to the OEM ECU (Master ECU) to reduce engine torque.

Internal closed loop strategy is available on the OEX or external option where a CAN messages can adjust the wastegate target and wastegate duty

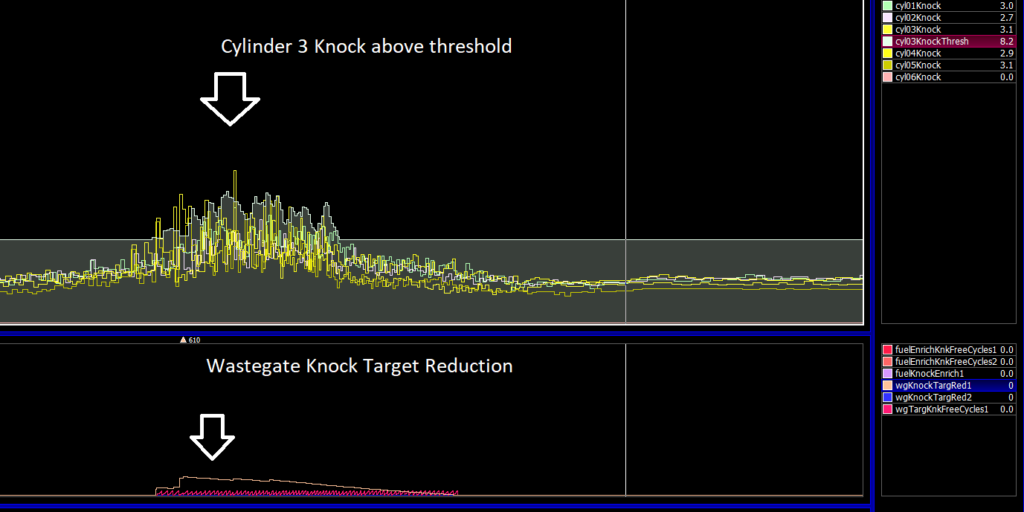

Knock Control

Two knock sensor circuits are present on the X20 hardware that allows the OEX to monitor per cylinder knock signals and display them in SCAL or datalogs to assist calibrators in the tuning process. There is also the ability to detect knock and adjust the boost targets, fuel calculations and timing requirements to the OEM ECU. In the event that the knock reaches a level that the calibrator is unhappy with it can set a LimpMode which can adjust sensor values or CAN messages to the OEM ECU (Master ECU)

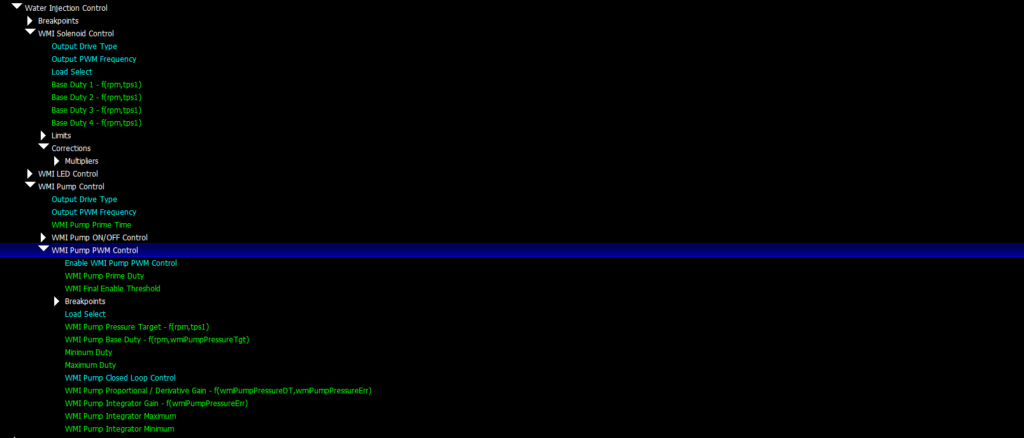

Water/Meth Injection Control

The water/methanol injection strategy from our Syvecs WMI has been incorporated into the OEX software allowing users to control 2 x solenoids and 2 x external pumps to provide the very best WMI control available. The strategies and monitoring systems provide a modern based control system with safety in mind. Closed loop pump control linked to flow is available and additional sensors can also be connected to the OEX to provide more data to further add safety into the system, like a Level Sensor, Flow sensor and Pressure sensor.

Sensor Rescaling

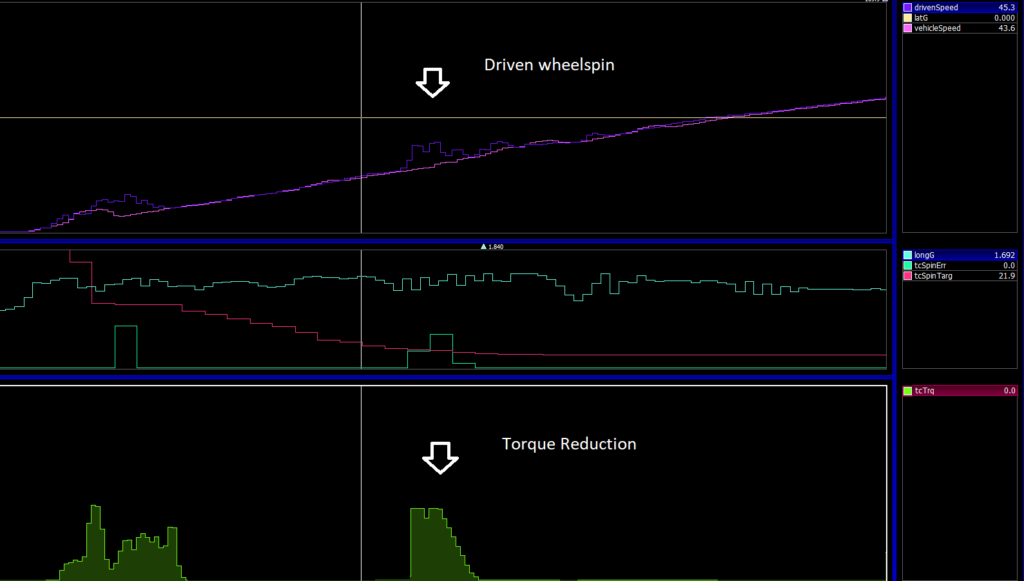

Traction Control

Many OEM traction control systems are designed for the engine's original torque levels. When the engine's torque is increased, these original systems may fail to function correctly. With the OEX, users can implement internal traction control strategies to monitor wheel speed signals, either through CAN or by wiring directly into the OEX inputs. Slip targets can be adjusted via calibration switches or OEM buttons from the factory car. When slip is detected, the control strategies will determine the extent of the slip and how best to reduce it, either by adjusting boost targets or sending a torque reduction signal to the OEM Engine ECU via CANbus.

Additionally, the Syvecs 100Hz GPS can be integrated with the OEX to monitor ground speed using GPS values. These values are then compared against the OEM four-wheel signals to calculate slip in a 4WD application.

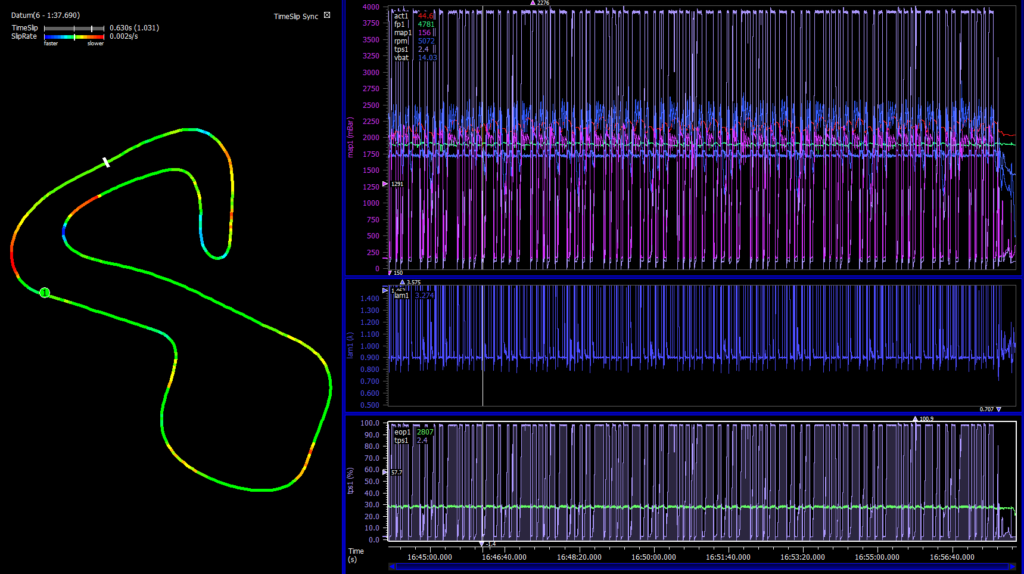

Datalogging

Many other strategies!

Specifications

Outputs

8 x Half Bridge Outputs (Support: Full Bridges, Lowside or HighSide Drive) (15Amp Peak (100ms) 8Amp Continuous)

12 x Low Side Outputs (12Amp Peak (100ms) 6Amp Continuous)

4 x DAC Outputs (-5v to 5v) – Max 65mA

Inputs

12 x Flexible Inputs supporting frequency, Sent, thermistor, bipolar

8 x 0-5v Voltage inputs

2 x NTK Lambda Inputs

2 x Knock Inputs

Communication Interfaces

USB For Updates, Configuration and memory stick logging

2 x CAN 2.0B interface for communication with other controllers or logging systems

1 x CANFD interface for communication

1 x Kline Interface

Power Supply

6 to 26V input voltage range

Physical

IP66 Sealed Automotive Spec -40c to 125c.

2 x 34 way Superseal 1.0 connectors

150mm x 150mm

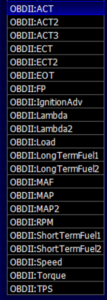

Predefined OEM CAN

Many OEM CAN streams are predefined in the OEX, but if your car is not listed then dealers can use the GenericRX CAN to custom define any CAN Stream or use the OBD2 protocol available in all cars since 2000 which allows the following to be received.