Page 1 of 1

Bosch 2-wire TBV settings

Posted: Tue Jan 08, 2019 3:41 pm

by tpepmeie

I'm running the 2-wire Bosch throttle bypass valve (0 280 140 516) with my S8/F88 ECU. The example calibration comes with some default settings (in parentheses), I'd like to know what you all use for:

PWM Drive frequency: (20Hz)

Minimum Duty: (10%)

Maximum Duty: (90%)

Unfortunately engine is not complete yet, so I can't just experiment.

Cheers,

Todd

Re: Bosch 2-wire TBV settings

Posted: Sat Jan 19, 2019 9:51 pm

by Trickster

I use 3 wire bosch valves, but I'm sure the frequency will be the same, 300hz works well

Graeme

Re: Bosch 2-wire TBV settings

Posted: Tue Jan 29, 2019 2:16 pm

by pavlo

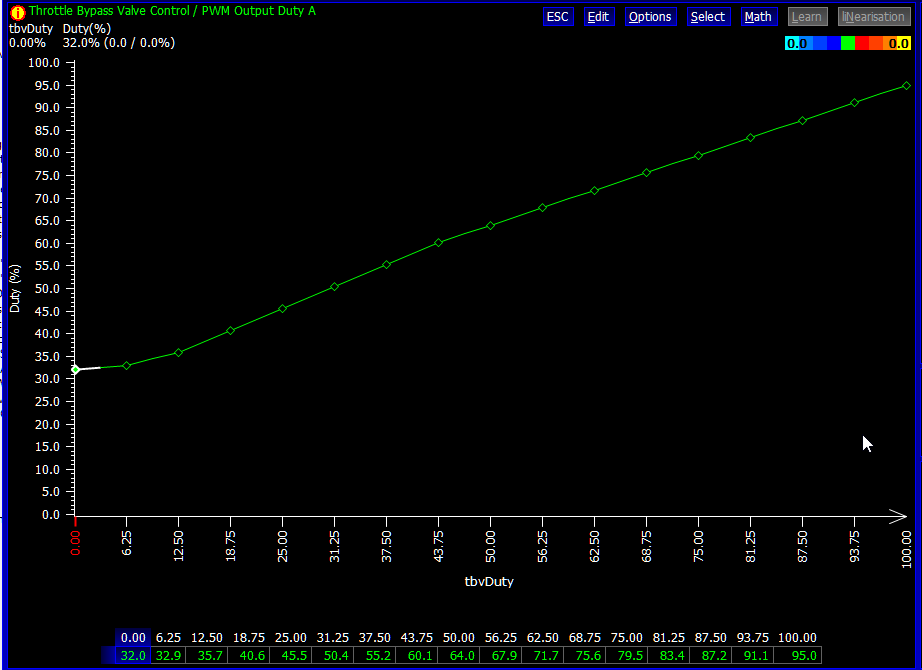

I used 300hz on a 2wire valve, it absolutely needs a flyback diode to work properly. My PWM output looks like this:

- bosch 2 wire.png (31.13 KiB) Viewed 130017 times

Re: Bosch 2-wire TBV settings

Posted: Sun Feb 03, 2019 12:11 am

by tpepmeie

pavlo wrote: Tue Jan 29, 2019 2:16 pm

I used 300hz on a 2wire valve, it absolutely needs a flyback diode to work properly. My PWM output looks like this:

bosch 2 wire.png

Can you say more about the diode? Why does it need that to work? Thanks.

Re: Bosch 2-wire TBV settings

Posted: Sun Feb 03, 2019 6:11 pm

by Slowie

Basically the diode allows you a greater range of usable duty cycle, by allowing the valve to close a bit quicker.

More technical explanations on this (as well as how to wire up the diode) are on this forum and others, but it boils down to the above.

Re: Bosch 2-wire TBV settings

Posted: Fri Feb 08, 2019 4:02 pm

by pavlo

Because an idle valve is a proportional device.

The diode stops the back EMF, (I think) the back EMF from the collapse the magnetic field will effect the field being reestablished during the next pulse, so you're average field strength is reduced. What we want is a more of an averaged constant current and therefore steady field of a required strength.

For a solenoid it doesn't matter because your back EMF occurs after the solenoid has moved and you don't care about the effect on the magnetic field between pulses.

Poor explanation but for proportional devices (ISCV, Electromagnets, Oil control valves etc) you want a diode and for solenoids that move from one state to another (injectors, boost solenoids, ignition coils) you don't want a diode. I would also use a diode for very big heafty coils like strong actuators, nitrous solenoids etc, because the back emf is just so big and risks damage.

Re: Bosch 2-wire TBV settings

Posted: Fri Feb 15, 2019 10:15 pm

by CT9A

Are there no diodes built in, in some outputs?

Re: Bosch 2-wire TBV settings

Posted: Tue Feb 19, 2019 9:08 am

by TimH

CT9A wrote: Fri Feb 15, 2019 10:15 pm

Are there no diodes built in, in some outputs?

Not on S6GP/S8/F88. There are diodes, as well as pullups to 5V or 12V, on some S6I/S6+/S7/S7+ outputs.

Re: Bosch 2-wire TBV settings

Posted: Tue Oct 08, 2019 9:08 am

by Trickster

I never noticed this thread had carried on, however I find it interesting about installing diodes on the idle valves if it makes them perform better.

I use 3 wire valves, so would I use 2 diodes in reverse bias from the 12v feed to each of the pwm controls from the ecu?

I have 2 valves in parralel to give me good anti lag, they work really well, but I'd rather reduce flyback if it could potentially be risky and also get better control

Graeme